The DeviDrill fits directly to the standard drill string and is fully compatible with the N-size wireline system. There is no need for additional water pumps, drill strings, or survey instruments. Devico’s survey tools are a fully integrated part of the tool, as they stay on board and measure while drilling (MWD).

Coring while steering provides a complete record of the geology. It leaves nothing in the hole – except a curve. The curvature or dogleg can be adjusted from zero to more than 20 deg/30 meters but is typically aimed at 9 deg/30 meters, which is the recommended curvature from most drill rod manufacturers.

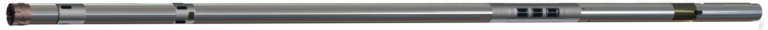

Steerable wireline core barrel

DeviDrill

The DeviDrill is an innovative directional core barrel based on the wireline core drilling technology used in exploration drilling. It drills the hole in a curve while at the same time collecting a 3m/10ft core sample, leading to the application name, Directional Core Drilling (DCD).

3 in

125.7 lbs

31.5 mm / 1.24”

5-9º/30 m /

5-9º/100 ft

300-1200

penetration rate:

3 m/h / 10 ft/h

Recommended parameters

Features

- Core in directional sections

- Low water consumption

- All necessary equipment in small start package

- Fits directly on N-size drill string

- High penetration rate in hard rocks

- Easily adjustable dogleg

- Higher dogleg used due to smoother curve

- Drill string rotation also during steering

- Directional surveys performed at hole bottom (through DeviDrill bit)

- Full size N-size borehole and no additional reaming required

Application areas

- Mineral exploration

- Branch hole drilling programs (delineation, definition, resource drilling)

- Deviation control

- Geotechnical investigation

SolGold about the DeviDrill

Request quote

Frequently asked questions about DeviDrill

Do we require additional mud pumps, drill strings or other equipment to use the DeviDrill?

No, the DeviDrill fits directly on the standard drill string and operates with similar flow rates as the regular N-sized wireline core barrels. During drilling the DeviDrill is rotated by the drill string at normal speed, typically 7-900 RPM, while at the same time steering the hole in a predefined direction and collecting core samples.

How sharply can the drill hole be turned when utilizing the DeviDrill?

We recommend an average turn of 9° per 30m drilled, or a radius of about 200 meters, to make the directional drilling efficient while avoiding excessive wear on the drill string.

How much savings can be expected from using DeviDrill?

Savings can come in may forms, including reduction in drilling meters leading to direct time & cost savings and indirect cost savings due to reduced core handling and logging, fewer drill sites leading to cost & environmental savings, and consistent target accuracy leading to cost savings. If you have a project where you believe directional coring could be used, we recommend contacting us. We prepare directional proposals at no cost, making it easy to see the benefit of DCD in your specific case.