Providing efficient and steady drill hole steering capability, the non-coring DeviDrill RSS is a suitable solution for any type of directional diamond drilling program, including deviation control, branch holes, geotechnical exploration, and pilot holes.

Just like the legendary DeviDrill (directional core drilling DCD technology), the DeviDrill RSS fits directly on an N-size wireline drill string and is operated with the same equipment and parameters as a standard core barrel. Unlike other directional drilling systems such as mud motors, additional water pumps and rod strings are not required.

A further range of innovative and patented solutions maximizes the rotation and feed transferred from the drill string to the drill bit, eases operation and secures stable and high production in both hard and compact to fractured rock formations. The DeviDrill RSS has no locking pin, continuous orientation capability (no muleshoe required), new and innovative valve technology for a broader operational range and is more robust with lower service requirements.

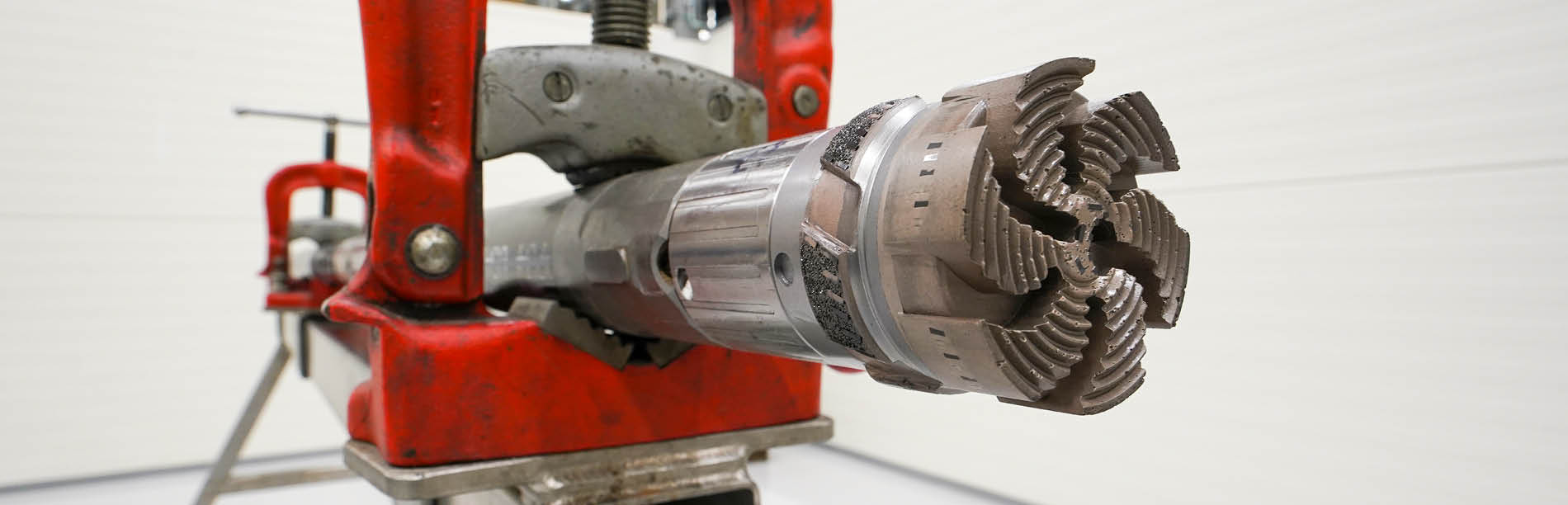

In front of the DeviDrill RSS sits a full-face drill bit specially designed for long life continuous operation. Making it especially suitable for achieving directional targets in broken ground with more ease than ever.

Integrated in the DeviDrill RSS is the DeviGyro, controlling the orientation, inclination, and direction as the DeviDrill RSS steers the hole towards the target. When drilling to deep exploration targets or requiring high accuracy this combination ensures that the targets are hit precisely in a time and cost-efficient manner.

All vital parts in the DeviDrill RSS are designed and optimized for robustness and durability, reducing downtime due to rod pulls whilst keeping repairs to a minimum, giving the operator full confidence in its performance.